Wangen塔位于美丽的Allgäu西部,是2024年Landesgartenschau打造的标志性地标和先锋木结构。斯图加特大学的“建筑综合计算设计和施工 (IntCDC)”对此进行了研究。这座高塔是第一座采用自成型结构木材组建进行分步搭建的结构。塔楼采用的独特木结构证明了天然可再生、取材当地、区与制造和节约型建筑结构的可行性,这些可行性均是通过综合的科学研究方法、材料明确的计算、数字制造和专业工艺共同得出的结果。

Set amidst the scenic landscape of the western Allgäu, the Wangen Tower is an architectural landmark and pioneering timber structure for the Landesgartenschau 2024. Based on research conducted at the Cluster of Excellence ‘Integrative Computational Design and Construction for Architecture (IntCDC)’ at the University of Stuttgart, the tower is the very first multi-level, walkable building to use self-shaped, structural timber components. The distinctive expression of the tower’s unique timber structure stand as a testament to the latent design possibilities in naturally renewable, locally sourced, regionally manufactured and resource-effective timber architecture, which can be uncovered through an integrative approach to scientific research, materially-informed computational design, digital fabrication and expert craftsmanship.

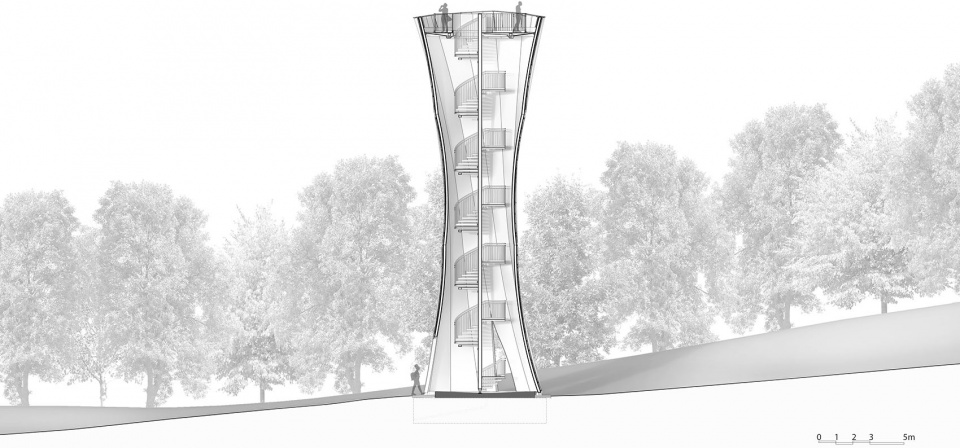

▼项目概览,Overall view © ICD_ITKE_IntCDC_University of Stuttgart

地标建筑和先锋木结构

An architectural landmark and pioneering timber structure

这座高塔已经为当地的地标,是一座富有表现力的木构建筑,呼应了Argen山谷的Landesgartenschau区域和周围连绵起伏的丘陵地带。塔身入口从三个不同方向优雅地打开,吸引人们一探究竟。面向Argen河流和相邻的冰碛丘柔和的轮廓,冰碛丘是一座由冰川形成的山丘,代表了当地前阿尔卑斯山冰川期的历史。在塔身内部,来访者能狗通过螺旋状的木结构来到上方的通透观景台,这里为人们提供了独特的视觉体验。当人们走到113级台阶顶部,能狗更加真切地从视觉和触觉上感受到塔身的木质结构。弯曲的木结构表面上光影交错,螺旋上升,顶部的视野也令人叹为观止。高塔弯曲的结构,在视觉上结合了不同历史文化和景观的特征,能够反映出中世纪小镇Wangen、Argen山谷区和阿尔卑斯山的壮丽景色。

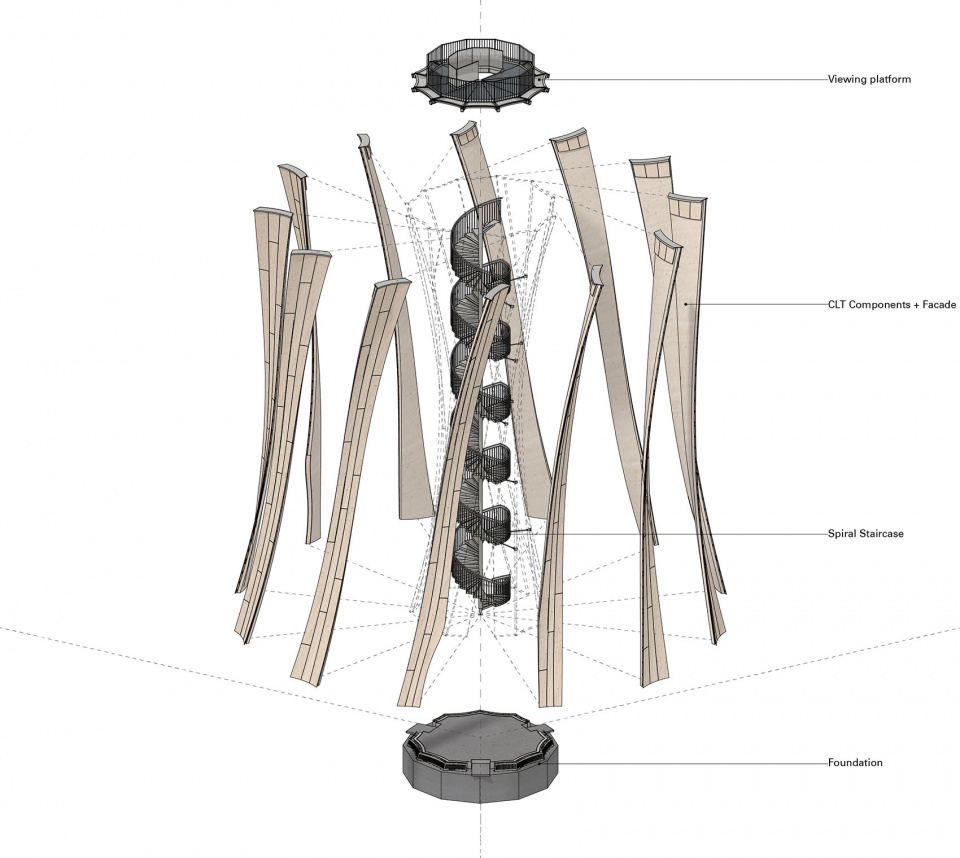

▼结构分析图,structure analysis © ICD_ITKE_IntCDC_University of Stuttgart

The tower constitutes a landmark that connects the Landesgartenschau site in the Argen valley with the rolling hills of the surrounding landscape through its expressive timber architecture. On the ground, the tower’s entrances unfold elegantly between the timber surfaces in three directions, creating an inviting, open space that orients towards the Argen river and the softly contoured top of the neighbouring drumlin, a glacially formed hill that marks the region’s pre-alpine glacial history. On the inside, the tower offers a unique spatial experience when ascending through the spiralling timber form towards the transparent viewing platform. Climbing the 113 steps to the top provides visitors with a visual and tactile connection to the materiality of the tower’s innovative timber structure. The articulated interplay of light and shadow on the curved wooden surfaces creates a sense of ascension towards the impressive reveal of the surrounding landscape at the top. With its curved upper edge, the tower curates the visual connection of various cultural sites and landscape features, framing views of the medieval town of Wangen and the Argen valley, while also offering stunning vistas of the Alps.

▼鸟瞰,Bird’s eye view © ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch

▼远观,Distant view © Roland Halbe

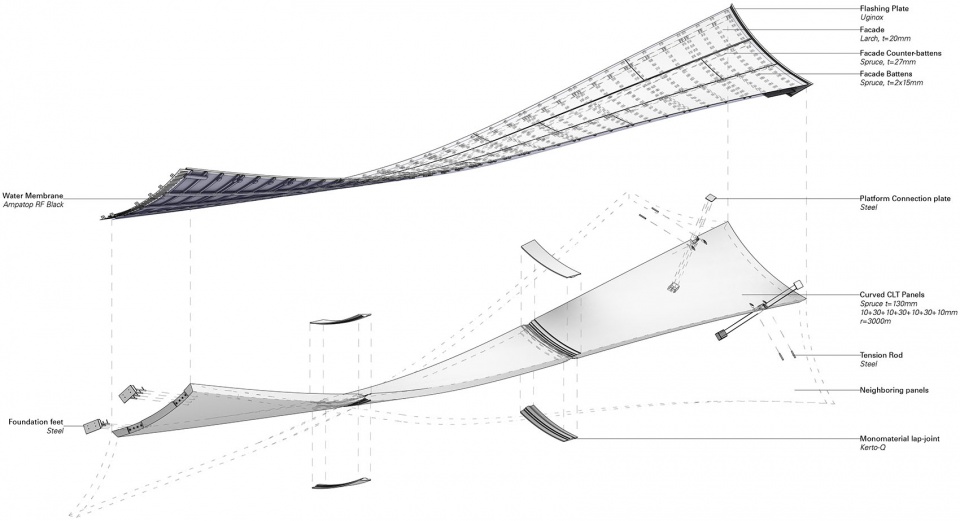

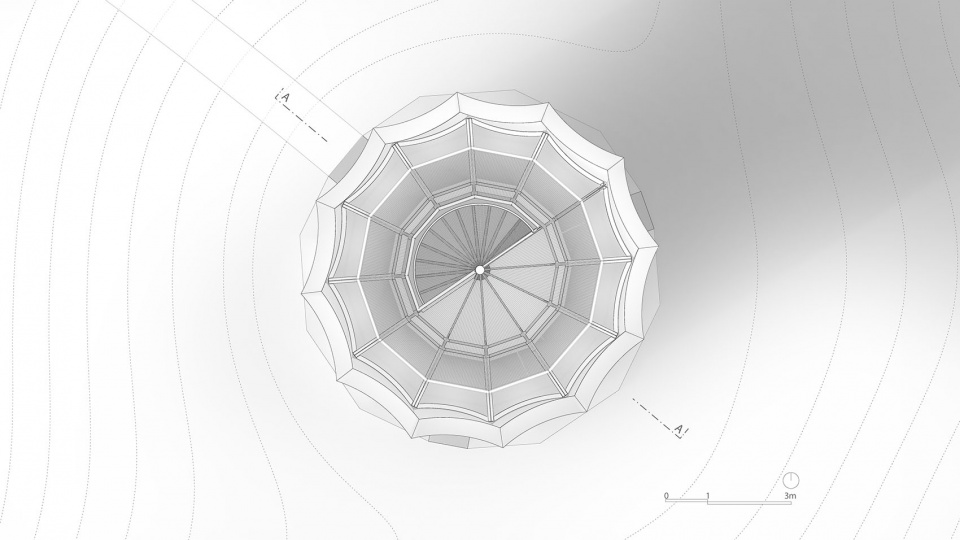

塔身高23米,是一次开创性的设计,由12个弯曲的交叉层压木材(CLT)组成,每侧结构的横截面都很纤长,仅有130毫米。整座塔的形状与CLT表面的曲率相结合,呈现出一种全新的活性木结构,形成独特的螺旋结构的同时,还能够承受所有决定性的水平风荷载。曲率为木材表面提供了额外的刚度,类似于波纹板那样。楼梯的阶梯由中央脊柱支撑其垂直荷载,在底部逐渐变窄,优雅地承载了更结构部件之间的精确荷载分布。设计者从项目伊始就保持了材料整合和制造约束计算,使得这座永久性的大楼能够以最先进的设计和高精度的建造最终落成。毫米级别的精确预制和精密铣削的连接细节保证了项目在现场仅用三天时间就搭建完成,同时还无缝搭建了钢制楼梯、玻璃天窗和观景台。高性能、高效资源的木结构为项目带来了独特的建筑表现力和鲜明的轮廓。

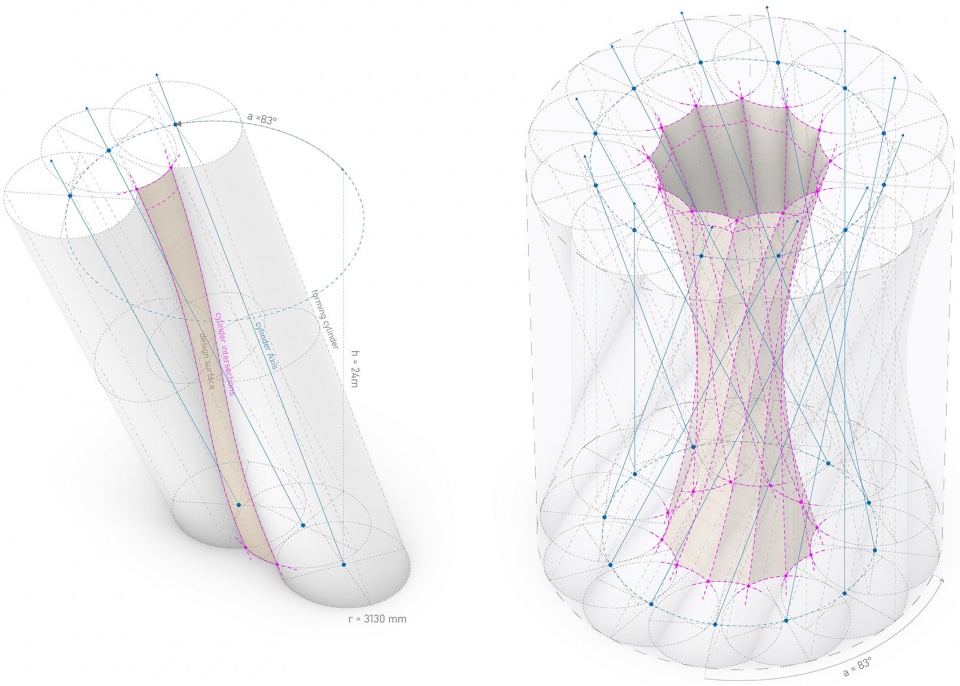

▼塔身曲率分析,curva analysis © ICD_ITKE_IntCDC_University of Stuttgart

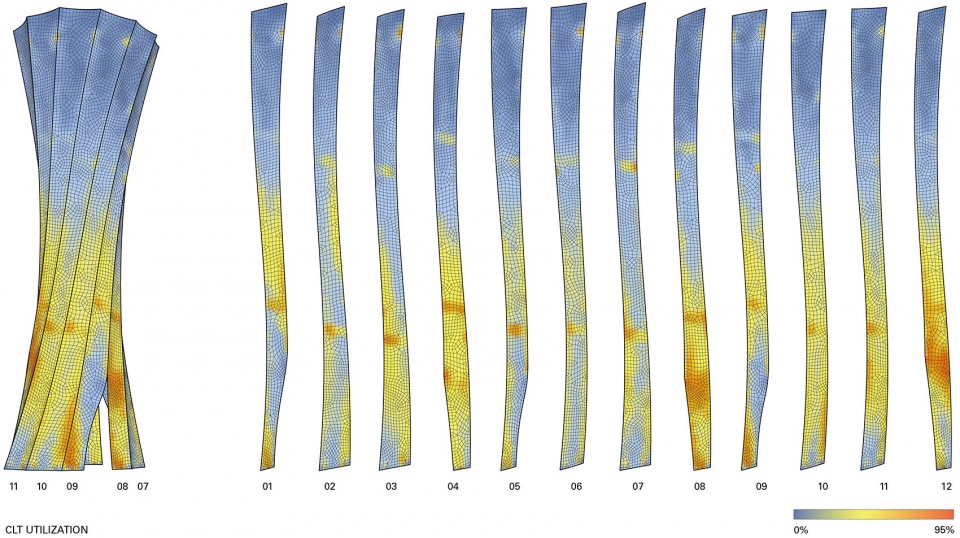

▼CLT板分析,CLT analysis © ICD_ITKE_IntCDC_University of Stuttgart

The tower’s 23m tall, pioneering structure is composed of 12 curved cross-laminated timber (CLT) segments, each with a slender cross-section of just 130 millimetres. The global shape of the tower, together with the local curvature of the CLT surfaces, results in a novel surface-active timber structure, which bears all the decisive horizontal wind loads and creates the tower’s distinctive, spiralled silhouette. The curvature provides additional stiffness to the timber surface, similar to a corrugated sheet. The central spine of the staircase supports the vertical live loads on the steps and elegantly highlights the precise load distribution among the various structural components by tapering at the base. Computational design strategies that integrate material behaviour and fabrication constraints from the onset are at the core for the advanced design and high-precision construction of this permanent research building. Millimetre-accurate prefabrication and precision-milled connection details enabled the onsite assembly to be completed in three days and allowed for seamlessly integrating the tower’s steel staircase, glass skylight and observation platform. The high-performance, resource-efficient timber structure results in an distinctive architectural expression with a visually striking silhouette.

▼顶视,Top view © ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch

▼仰视塔身,Looking up at the tower © ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch

预测和生产自成型木材部件

Predicting and producing self-shaped timber components

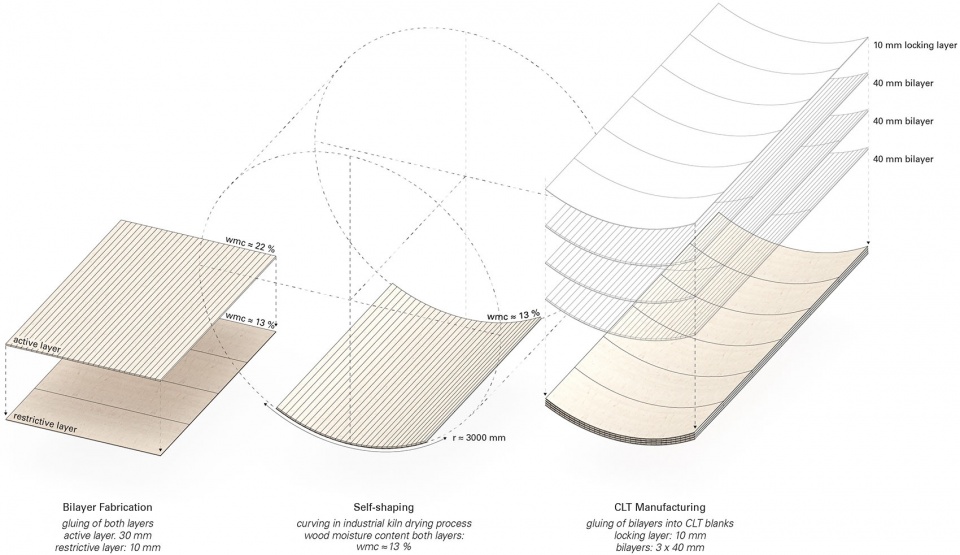

Wangen塔的顶部设有观景台,这是第一座使用弯曲组件打造的多层建筑,设计者根据这些弯曲门木质组件受潮收缩产生的大规模自成型制造而成。通常情况下,木结构建筑是不希望出现受潮收缩和变形情况的,但是,因为云杉球果会随着环境的干湿程度而改变其鳞片的形状,受到这个生物学案例的启发,设计者将其原理运用于控制弯曲木材组件之中。在本项目中,木结构中的水分在标准工业干燥过程中降低,根据其特性能够精确收缩其形状到计算预定的目标曲率。

▼结构元件,structural elements © ICD_ITKE_IntCDC_University of Stuttgart

The Wangen Tower, with its viewing platform at the top, is the first structure with multiple inhabitable levels to use curved components based on large-scale self-shaping manufacturing derived from the moisture-induced shrinking of wood. Typically, moisture-induced shrinkage and deformation is considered undesirable in timber construction. However, inspired by biological examples like the spruce cone, which reacts to changing ambient humidity levels with a shape change of its scales, similar principles can be applied to control the self-forming of curved timber components. Here, precise shape change to a computationally predetermined target curvature is driven solely by the wood’s characteristic shrinkage as its moisture content decreases during a standard industrial drying process.

▼塔身全貌,The whole tower © ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch, Roland Halbe

项目使用的自成型交叉层压木材(CLT)组件取材于当地,这种双层板被生产为平板样式,每块平板由30毫米厚的“活动”层和交叉层的10毫米“限制”层组成。与典型的工业木材生产相反,这种木板是在轻微风干后进行加工。其中,含水量较高的“活动”层在平板真空压机中层被压到“限制”层上,压层之后,平板还会经历受控的窑干过程,其中活动层沿着垂直于木材纤维方向收缩,这样能够准备地将面板按照预测的形状进行弯曲。三块自成型板与10毫米薄的弹性弯曲锁定层相互堆叠和层压,最终形成了稳定且精确弯曲的130毫米CLT面板。

▼剖透视效果图,sectional perspective rendering © ICD_ITKE_IntCDC_University of Stuttgart

Locally sourced spruce was used to craft the self-shaped cross-laminated timber (CLT) components. The self-shaping bilayer plates are designed and produced as flat panels, each consisting of a 30-millimetre thick ‘active’ layer and a cross-laminated 10-milimetre thin ‘restrictive’ layer. Contrary to typical industrial timber production, the wood boards get processed after slight air drying. The ‘active’ layer with higher moisture content is laminated to the restrictive layer in a flat vacuum press. After lamination, the flat plates undergo a controlled kiln drying process where the active layer shrinks perpendicularly to the fiber direction of its boards, effectively shaping the panels into their predicted curved form. Three self-shaped bilayer plates together with 10-millimeter thin elastically bent locking layer are stacked and laminated to create a final, dimensionally stable and accurately curved 130-millimeter thin CLT panels.

▼入口处,Entrance © ICD_ITKE_IntCDC_University of Stuttgart

注重材料、节约资源的木结构建筑

Material-informed, resource-effective timber construction

为了充分利用CLT面板的曲率,和资源高效、形式灵活的木结构,设计者综合运用了材料计算和精确的数字预制手法。这些木材之间的连接一句了数字模型,设计者通过CNC铣削精确的实现。塔身12个23米长的结构段都是由独立的CLT构件组成,这些组件采用了5轴CNC的切割方式,能够将各个材料精准地连接在一起,以保证每个方向的受力;CLT元件的连续性也使横截面的尺寸保持恒定。衔接的位置和形状都经过了精准的计算,以满足结构标准和建造限制,同时也能最大限度地减少切屑总量。

To utilize the curvature of CLT panels for a highly resource-effective, form-active timber structure, material-informed computational design and precise digital prefabrication was employed in an integrative manner. The innovative timber connections were derived directly from the digital model and precisely materialized using CNC milling. Each of the twelve 23-metre long structural segments of the tower is made from three individual CLT elements, which are 5-axis CNC cut and precisely joined using a newly developed mono-material lapped joint to transmit forces in all directions and creating continuous CLT elements while maintaining constant cross-sectional dimensions. The exact position and geometry of the joints were optimized to fulfil both structural criteria and fabrication constraints, while minimising the total amount of off-cut material.

▼塔内楼梯,Stairs © ICD_ITKE_IntCDC_University of Stuttgart, ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch

▼塔内仰视,Looking up from inside the tower © ICD_ITKE_IntCDC_University of Stuttgart

▼楼梯与塔身近景,Close-up of the staircase and tower © ICD_ITKE_IntCDC_University of Stuttgart_Nina Baisch

▼楼梯细部,Stairs detials © ICD_ITKE_IntCDC_University of Stuttgart

12个塔身组件预先在工厂中成对组装,这样能够节省在现场的施工时间。链接CLT结构和楼梯的钢制连接组件,和立面上168块单独的落叶松板大部分也在工厂进行了预安装。各类塔组件在现场仅用3天时间就安装完毕,并被安置在有再生混凝土和低碳水泥基座上,支撑着内部的楼梯和观景平台。螺旋楼梯的各个部分和跨度为7米的观景平台都是从上方置入塔内的。

In the factory, the 12 tower components were pre-assembled into pairs of two, a key step to minimise on-site construction time. Additionally, the steel connectors, which interface between the CLT structure and the staircase, as well as most of the 168 individually crafted larch panels of the façade were pre-mounted in the factory. Onsite, the tower components were installed on a foundation made from recycled concrete with CO2-reduced cement in three days only. The resulting structural timber shell supports the staircase and observation platform. Segments of the spiral staircase, as well as the 7m-spanning observation platform, were inserted into the tower from above.

▼工厂预组装,Factory pre-assembled © ICD_ITKE_IntCDC_University of Stuttgart

▼运送至场地,Delivery to the venue site © ICD_ITKE_IntCDC_University of Stuttgart

▼现场安装,On-site installation © ICD_ITKE_IntCDC_University of Stuttgart_Christoph Morlok

本项目以其独特的外观和创新的结构设计实现了传统木材的现代化表达,既展示了综合利用科学研究方案、材料计算设计、数字预制和专业工艺对自然可再生的拓展,又实现了本地采购、区与制造以及资源节约型木材建筑的设计目标。

The Wangen Tower’s distinctive form and innovative structure is a truly contemporary architectural expression of the traditional construction material wood. It shows how an integrative approach to scientific research, materially-informed computational design, digital prefabrication and expert craftsmanship significantly expands the design space of naturally renewable, locally sourced, regionally manufactured and resource-effective timber architecture.

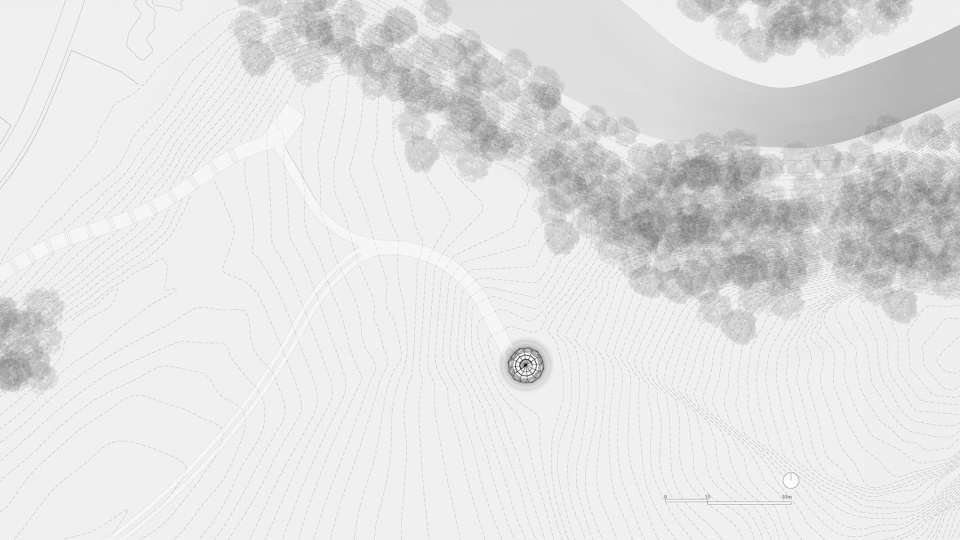

▼总平面图,master plan © ICD_ITKE_IntCDC_University of Stuttgart

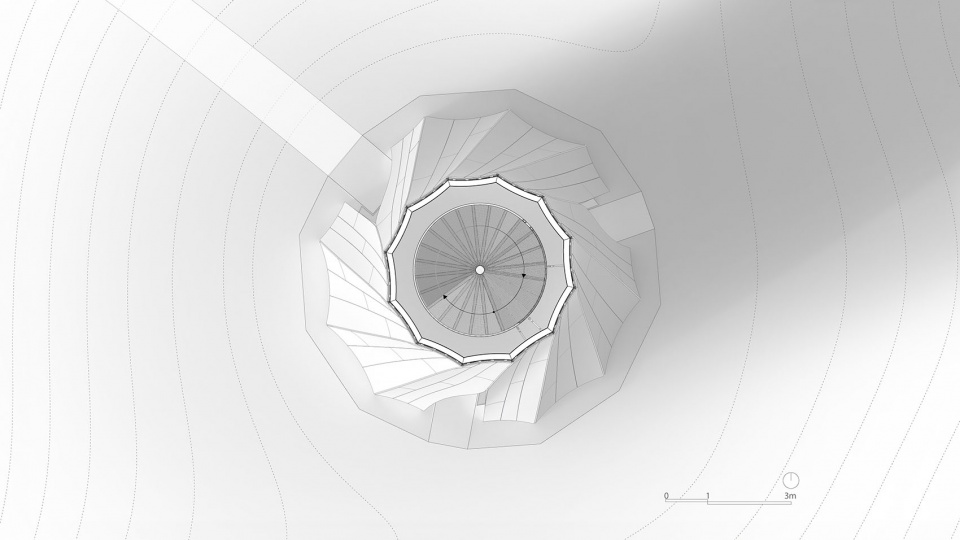

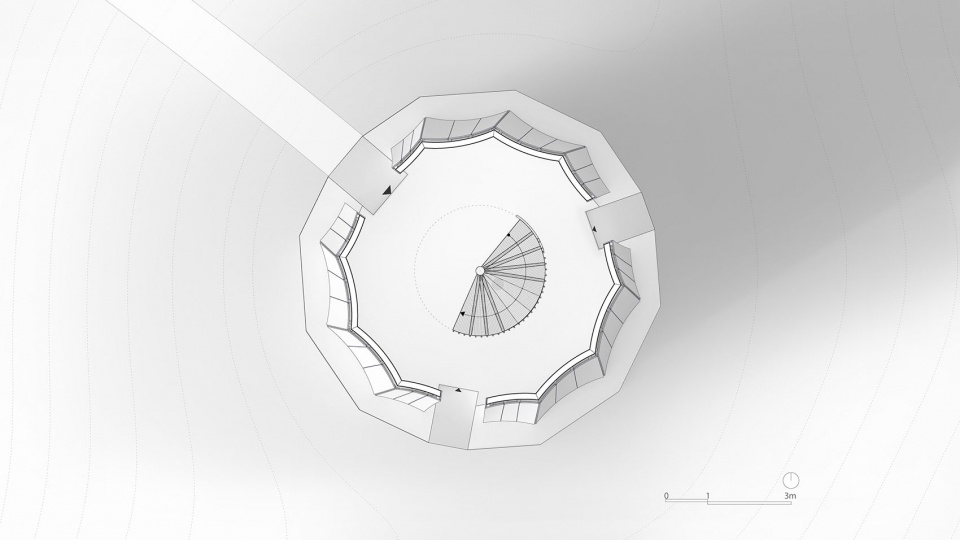

▼平面图,plan © ICD_ITKE_IntCDC_University of Stuttgart

▼立面图,elevation © ICD_ITKE_IntCDC_University of Stuttgart

▼剖面图,section © ICD_ITKE_IntCDC_University of Stuttgart